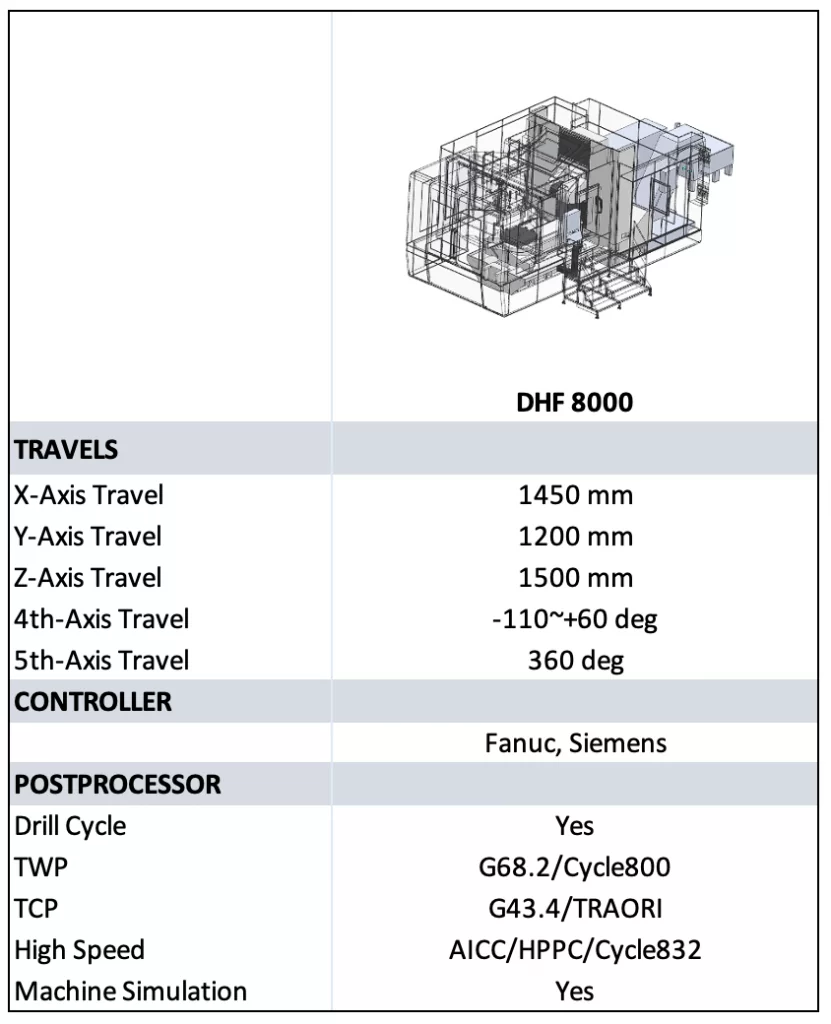

dOOSAN DHF 8000 5ax series postprocessor

Introduction to the DHF 8000 by DN Solutions

The DHF 8000 from DN Solutions is one of the most advanced 5-axis horizontal machining centers, designed specifically for machining large, complex parts with high precision. This machine is ideal for applications in the aerospace, automotive, and energy industries, where high rigidity and powerful cutting capabilities are essential.

Key Features of DHF 8000:

-

X-axis travel: 1450 mm, Y-axis travel: 1200 mm, Z-axis travel: 1500 mm, suitable for large workpieces.

-

4th-axis rotation range from -110° to +60° and 5th-axis full 360° rotation, providing extensive machining flexibility.

-

Fanuc or Siemens controllers, supporting advanced programming features such as TCP (Tool Center Point), TWP (Tilted Work Plane), and high-speed machining.

-

Integrated advanced control technology, optimizing machining processes and boosting production efficiency.

Post Processor for DHF 8000 – DN Solutions

Why Do You Need a Custom Post Processor for DHF 8000?

Due to the unique design of the DHF 8000, using a customized post processor is crucial to fully leverage its 5-axis machining capabilities. A well-optimized post processor will:

-

Optimize toolpaths, reducing programming and machining time.

-

Ensure accurate G-code generation, preventing syntax errors and coordinate mismatches.

-

Fully support advanced functionalities, including TCP, TWP, and high-speed machining.

Standard post processors often lack comprehensive support for these features, requiring manual NC code modifications, increasing error risks, and reducing production efficiency.

OptiTech – The Ultimate Post Processor Solution

OptiTech provides customized post processors for NX CAM, Mastercam, and SolidCAM, ensuring seamless operation of DHF 8000 with advanced functionalities:

-

Full support for drilling cycles.

-

Integration of G68.2 (Fanuc) or Cycle800 (Siemens) for TWP.

-

TCP support with G43.4 (Fanuc) or TRAORI (Siemens).

-

High-speed machining with AICC, HPPC (Fanuc), or Cycle832 (Siemens).

-

Accurate machine simulation in NX CAM ISV or Vericut for collision detection.

With these optimizations, OptiTech’s post processors help businesses increase productivity, minimize errors, and optimize 5-axis CNC machining processes.

Get a Free Trial of the DHF 8000 Post Processor!

If you are using a DHF 8000 and need a post processor for NX CAM, Mastercam, or SolidCAM, sign up now for a free trial at OptiTech Post Library.