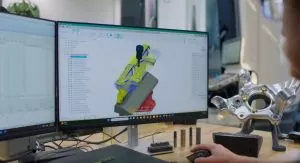

In today’s highly competitive manufacturing world, faster and more efficient programming is the key to staying ahead. That’s exactly why CAM Assist – the AI-powered platform developed by CloudNC – is gaining massive attention across the CNC community.

Over $100 Million Invested in a New Future

CloudNC isn’t just another tech company. They’ve invested over $100 million USD to build CAM Assist – an AI system capable of generating CNC toolpaths in just minutes, helping engineers cut traditional programming time by 60–80%.

What sets them apart is that their development team includes both software engineers and real machinists, ensuring CAM Assist is grounded in real-world manufacturing logic, not just theory.

Not Magic – Just Smarter Programming

Let’s be clear: CAM Assist is not a one-click solution. You can’t simply import a CAD file and expect perfect G-code instantly.

To unleash its full potential, you must first create a solid foundation:

-

✅ A complete tool library with length of cut, depth, SFM, chip load, etc.

-

✅ Proper part and fixture setup

-

✅ Clearly defined material parameters

Once the environment is ready, CAM Assist will analyze your part geometry, evaluate countless strategies, and automatically generate toolpaths.

Human Programmers Still Matter – More Than Ever

CAM Assist may deliver 60–80% of the program, but the last mile still needs your expertise:

-

✅ Check for tool collisions or overcutting

-

✅ Fine-tune step-downs, feedrates, lead-ins

-

✅ Adapt the strategy to your shop’s reality

In many cases, CAM Assist even teaches you new programming approaches. It offers alternative strategies that may surprise even seasoned programmers – expanding your knowledge while saving time.

Your Tool Library is Everything

The heart of CAM Assist is your tool database.

-

The more tools and detailed parameters you provide, the smarter the AI becomes.

-

Use this opportunity to create a unified, company-wide tool standard, based on the best practices of your top programmers.

As one expert puts it:

“AI only works as well as the environment you give it. Build the right playground, and it will deliver incredible results.”

Beyond Automation – This Is Acceleration

Imagine this: instead of each programmer starting from scratch, one person can use CAM Assist to prepare 60–80% of the work for upcoming jobs.

This approach helps teams:

-

🚀 Pre-stage dozens of parts

-

🔧 Focus experts on complex jobs

-

💰 Boost throughput and profit margins

AI doesn’t replace your job – it gives you time back. Time to focus on the creative, critical tasks that machines still can’t do.

Conclusion: AI Won’t Replace You – It Will Empower You

CAM Assist isn’t a replacement for skilled machinists – it’s a tool that makes them faster, smarter, and more productive.

If you’re a CNC shop owner, a CAM engineer, or simply someone looking to push your productivity further — CAM Assist is the tool you’ve been waiting for.

🔗 Learn more here: CAM Assist – AI-Powered CNC Programming