100%

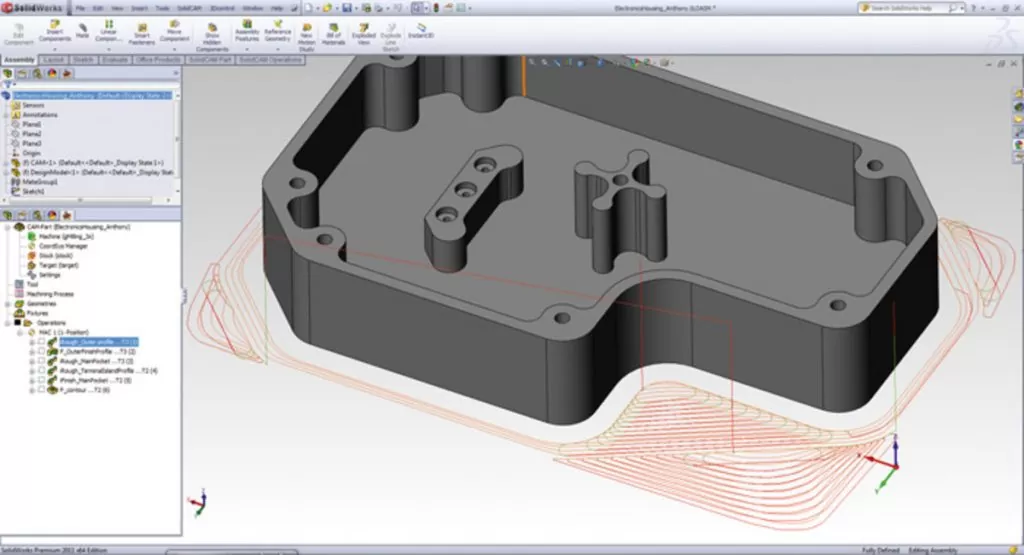

Integrated with SolidWorks. Toolpaths automatically update when the SOLIDWORKS model changes.

70%

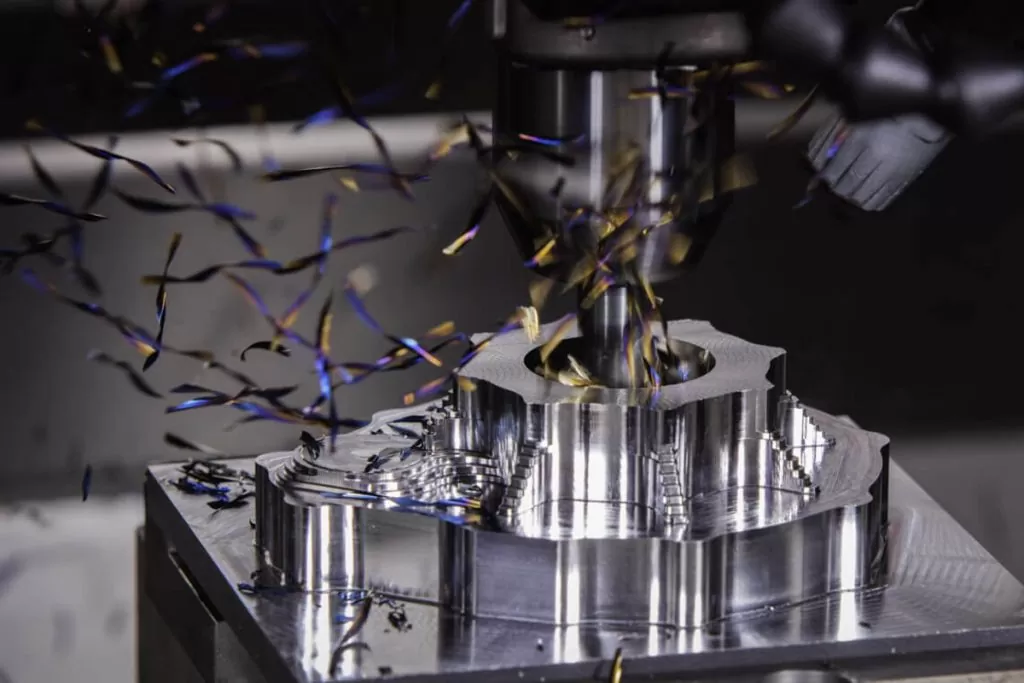

70% and more Machining Time Reduction with imachining technology

5X

5X longer tool life

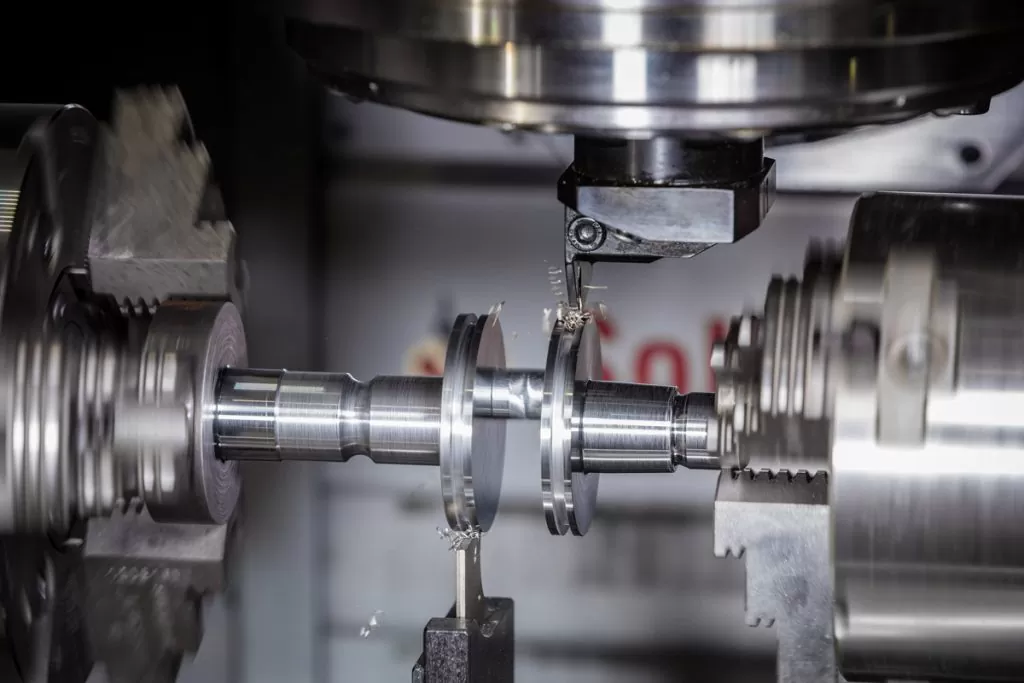

High Performance CNC Machining

SolidCAM’s exclusive and patented iMachining is an intelligent high speed milling technology that creates significantly faster and safe CNC programs to machine mechanical parts with first part success, while maximizing tool life. iMachining’s features and algorithms give you unbelievable cycle time savings and unmatched tool life performance while providing you with perfect machining feeds and speeds, the first time, every time.

Our patented iMachining Technology Wizard automatically calculates and optimizes cutting feeds and speeds for each point of the toolpath. This maintains constant cutting force on the tool, enabling full tool depth of cut, and reducing multiple passes and tool wear..

iMachining keeps the cutting angle between defined minimum and maximum values. In addition, it uses variable feed to maintain constant spindle load by automatic feed adjustment for varying width of cut. When cutting angle is reduced for morphing efficiency, higher federates are used.

SolidCAM CAM Modules

2.5D & iMachining 2D

The Most Powerful & Easiest Way to create 2.5D CNC Milling Toolpaths: Full Interactive Control + Feature Recognition.

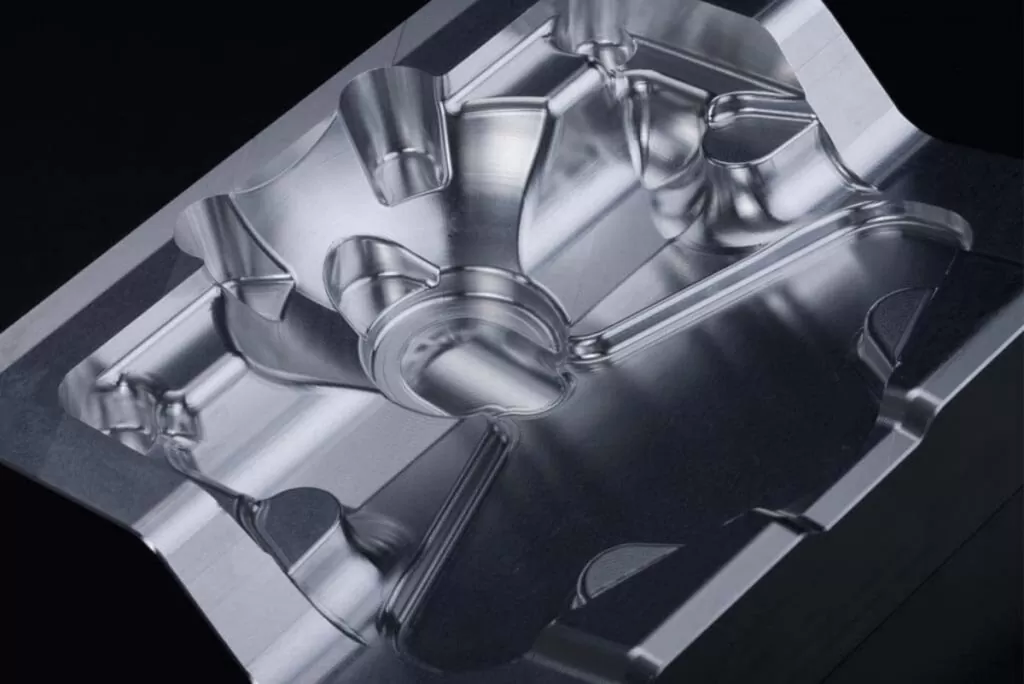

iMachining 3D

Proven iMachining Technology Algorithms Advance Even Further for Amazing 3D Milling.

High Speed Surfacing (HSS)

High Speed Surface Machining of Localized Surfaces

HSM

Powerful Roughing & Finishing Tool Paths for 3D Machining.

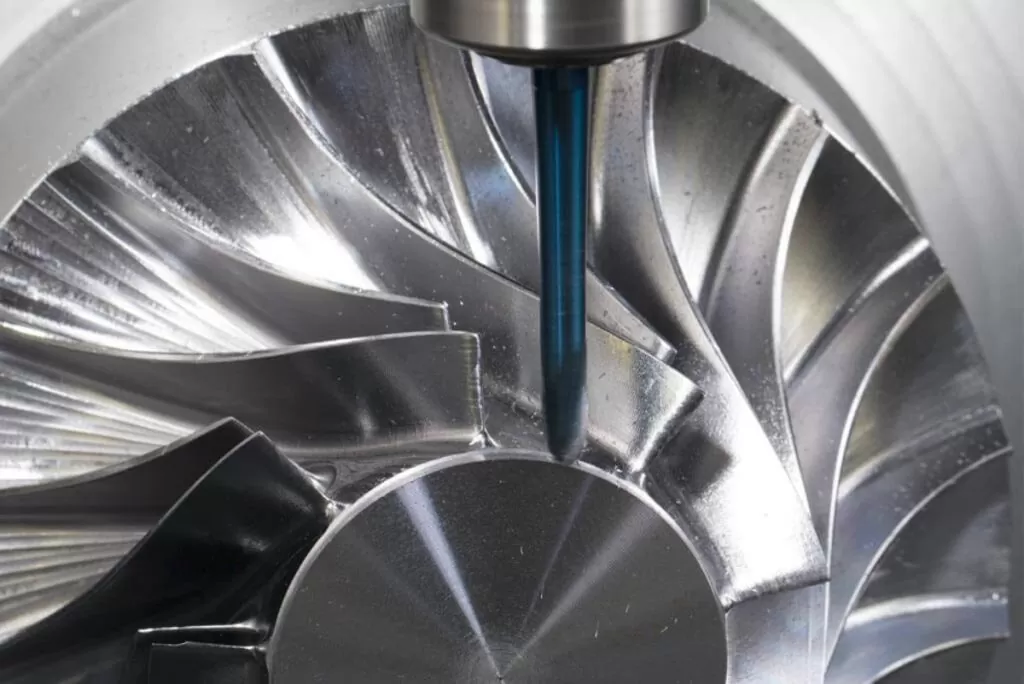

5 Axis Machining

SolidCAM’s Proven & Powerful Simultaneous 5-Axis Machining.

Millturn & Swiss Type

Get the Most Out of Your Mill-Turn CNC Machines

Contact Us!