In the world of precision manufacturing, time is money — especially when it comes to CNC programming. For MSP Manufacturing, a company serving the aerospace and defense sectors, finding experienced programmers had become a critical challenge. But in mid-2024, they discovered a game-changer: CAM Assist, the AI-powered programming engine from CloudNC.

And the results speak for themselves:

A programming task that used to take 2 hours now takes just 27 minutes.

The Bottleneck: Skilled Programmers in Short Supply

Johnny Goody, President of MSP Manufacturing, explained that one of the company’s biggest pain points was a lack of skilled CAM programmers in their geographic region.

“Programming was a bottleneck for us. There just weren’t many people we could hire locally.”

MSP handles a wide range of parts — including instrument cases, clamps, switch cards, cooling ducts, and more — and much of the work is build-to-print, tailored to customer specifications. Each job required significant programming time before it could go to the machine.

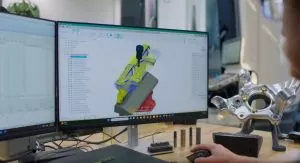

The Solution: AI-Powered CAM

In July 2024, MSP integrated CAM Assist into their workflow. The results were immediate and measurable:

-

CAM Assist handled 70–90% of the programming workload

-

Programming time dropped from 90–120 minutes to just 27 minutes

-

Engineers simply reviewed, fine-tuned, and certified the toolpaths before production

“Multiply that time savings across 10+ parts a day, and it’s easy to see how the ROI adds up fast,” said Goody.

Financial Impact: Higher Throughput, Lower Overhead

CAM Assist has helped MSP avoid the need to hire more staff, which directly reduces overhead — a critical cost component in their shop, where overhead accounts for nearly two-thirds of total costs.

-

No need for new hires

-

Same team, more output

-

Consistent pricing, higher profit margins

“We’ve been able to keep our pricing steady while increasing profit margins on every job.”

Beyond the Shop Floor: Unlocking Leadership Bandwidth

Goody also noted a personal benefit: CAM Assist has taken over much of the routine programming work he used to manage, allowing him to focus on business development and customer relationships.

“It can do a lot of what I used to do. Now I can travel more, meet customers, and grow the business.”