In the modern manufacturing landscape, the demand for high precision and efficiency in CNC machining is ever-growing. NX CAM stands out as a powerful tool for mill-turn machining, offering a range of advanced features that streamline the process and enhance productivity. Here are four compelling reasons to use NX CAM for your mill-turn operations.

1. Automatic Stock Calculation with IPW

One of the standout features of NX CAM is its ability to automatically calculate the in-process workpiece (IPW). This capability allows the software to dynamically track the material removal process, providing real-time updates on the remaining stock. By doing so, NX CAM helps machinists make more informed decisions, reduces errors, and improves overall machining efficiency.

- Enhanced Precision: Accurate tracking of material removal ensures that the machining process is precise and consistent.

- Reduced Waste: By optimizing the use of raw materials, NX CAM minimizes waste and maximizes resource utilization.

- Time Savings: Automated calculations save time that would otherwise be spent on manual adjustments and recalculations.

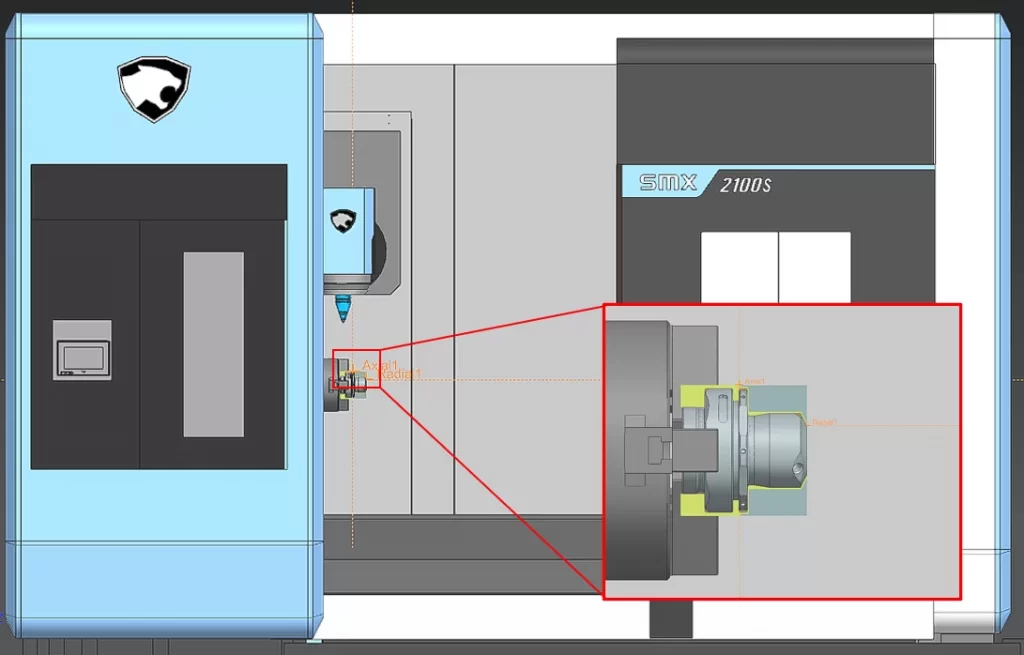

2. Integrated Mill-Turn Environment

NX CAM provides an integrated environment for both milling and turning operations. This seamless integration allows users to perform complex machining tasks without switching between different software platforms.

- Simplified Workflow: Having a unified platform for both milling and turning simplifies the workflow and reduces the learning curve for operators.

- Improved Collaboration: Teams can collaborate more effectively, as all machining processes are managed within the same environment.

- Increased Efficiency: Integrated mill-turn capabilities streamline the setup and execution of machining tasks, leading to faster project completion.

3. Easy Control with User-Defined Events (UDEs)

User-Defined Events (UDEs) in NX CAM offer a flexible and powerful way to control machining operations. UDEs allow users to insert specific commands or events into the NC program, providing precise control over the machining process.

- Customization: UDEs enable customization of the machining process to meet specific requirements and preferences.

- Flexibility: Machinists can easily modify and control various aspects of the machining process, such as tool changes and coolant flow, without altering the core NC code.

- Improved Accuracy: By defining specific events, users can ensure that the machining process adheres to precise specifications, reducing the risk of errors.

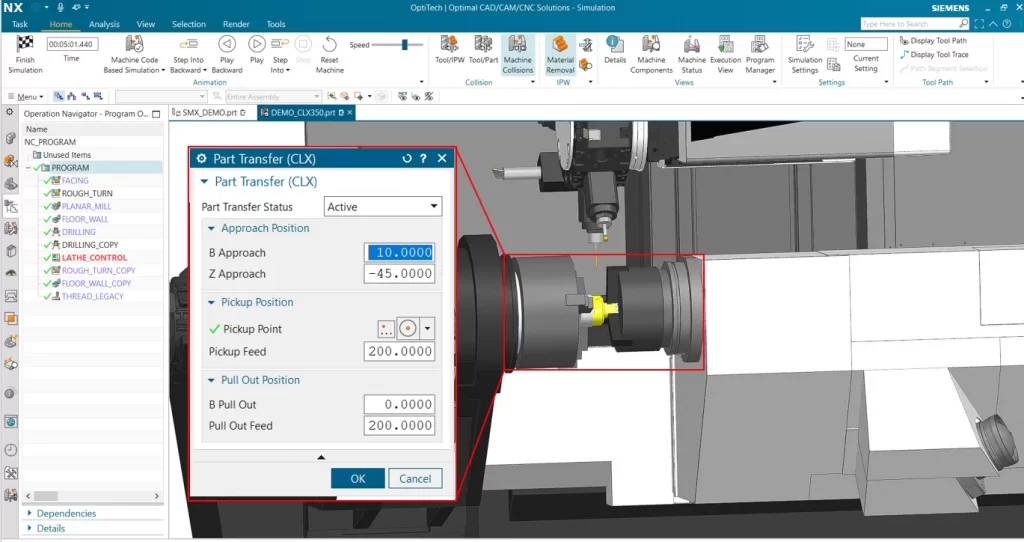

4. Machine Simulation with NC Code

NX CAM’s advanced simulation capabilities allow users to perform detailed machine simulations using the actual NC code. This feature ensures that the programmed operations will be executed correctly on the physical machine, reducing the risk of errors and collisions.

- Realistic Simulations: Simulations using NC code provide a realistic representation of the machining process, helping users visualize and verify operations before actual production.

- Error Prevention: By identifying potential issues in the simulation phase, NX CAM helps prevent costly mistakes and machine downtime.

- Confidence in Execution: Accurate simulations give machinists confidence that the NC code will perform as expected, leading to smoother and more reliable machining operations.

Learn more about machine simulation.

Try a 30-Day Free Trial of Optitech’s Postprocessors

Optitech offers a library of over 1,000 postprocessors, ensuring you have the right tools for your specific machining needs. Download a 30-day free trial to experience the benefits first-hand and see how Optitech can optimize your CNC operations.

Explore Optitech’s NX post library.

Conclusion

NX CAM offers a comprehensive suite of features that make it an ideal choice for mill-turn machining. From automatic stock calculation and an integrated mill-turn environment to easy control with UDEs and detailed machine simulations, NX CAM enhances precision, efficiency, and reliability in CNC machining. Adopting NX CAM for your mill-turn operations can lead to significant improvements in productivity and quality.