Introduction to NX X Manufacturing Standard

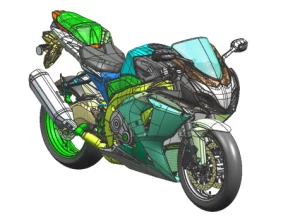

NX X Manufacturing Standard is a powerful CAD/CAM software package from Siemens, designed to automate CNC programming for simple geometric parts. With integrated CAD/CAM functionality, this software supports 2.5-axis machining, turning, drilling, and on-machine probing. It is an ideal solution for small and medium-sized businesses seeking to optimize machining processes without requiring advanced features like 5-axis machining.

Key Features

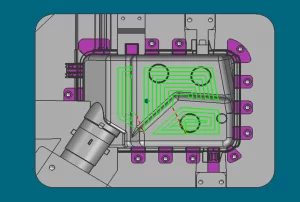

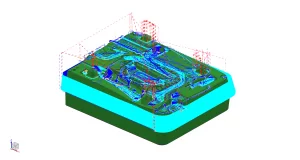

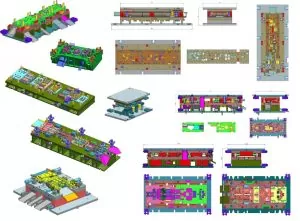

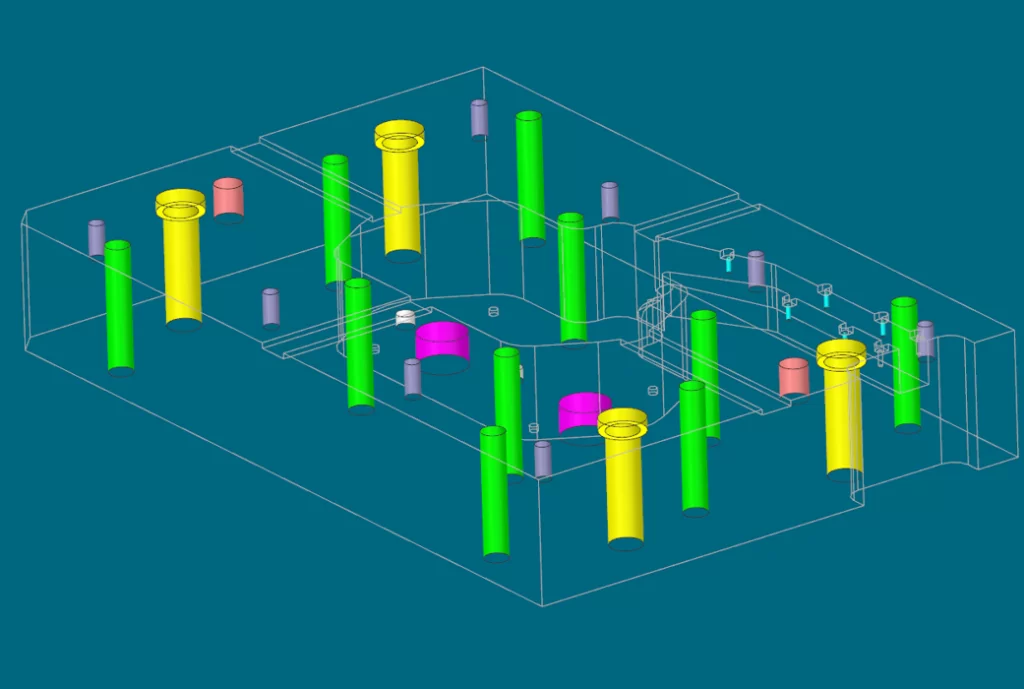

Automated Programming

- Automatically identifies and programs machining features directly from 3D models, reducing programming time by up to 90%.

- Integrated strategies for turning, milling, and drilling to meet standard production needs.

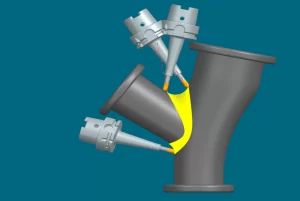

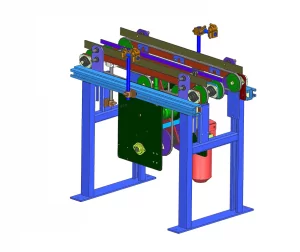

High-Speed Machining Tools

- Implements high-speed cutting strategies to optimize cycle times and reduce tool wear, especially useful for machining hard materials.

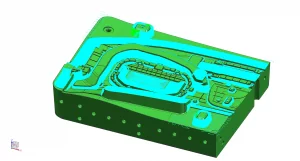

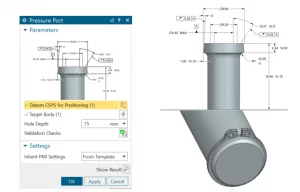

Toolpath Simulation and Verification

- Offers built-in machining simulation to detect errors and optimize operations before running on actual CNC machines.

Cloud-Based Postprocessing

- Includes Post Hub, featuring over 1,200 ready-to-use postprocessors compatible with various CNC machines from major manufacturers like Haas, DMG MORI, and Okuma.

Tool Library and Manufacturing Data Management

- Provides an intuitive tool library for managing and utilizing tool data from supplier catalogs, minimizing manual input and errors.

Benefits

- Save Time and Production Costs: Enhance programming efficiency and reduce production preparation time.

- Easy Scalability: Upgradeable with additional features through a token-based licensing model.

- Comprehensive Integration: Supports end-to-end workflows from design to manufacturing on a single platform, improving productivity and quality.

Pricing for NX X Manufacturing Standard

NX X Manufacturing Standard is available as a SaaS subscription with a reference price of approximately 7,000 USD per year. The exact price may vary depending on the specific requirements of the business, the number of users, and additional options.

Conclusion

NX X Manufacturing Standard is an ideal solution for businesses seeking to automate CNC programming at a reasonable cost. With robust integration, advanced simulation capabilities, and Siemens’ support, this package is perfect for enhancing production processes and reducing costs.