Introduction

In the realm of CNC (Computer Numerical Control) machining, precision and accuracy are crucial for producing high-quality parts. A vital component in achieving this precision is the postprocessor. But what exactly is a postprocessor, and why is it so important in CNC machining? In this blog post, we will delve into the definition, function, and significance of a postprocessor in the manufacturing process.

Definition of a Postprocessor

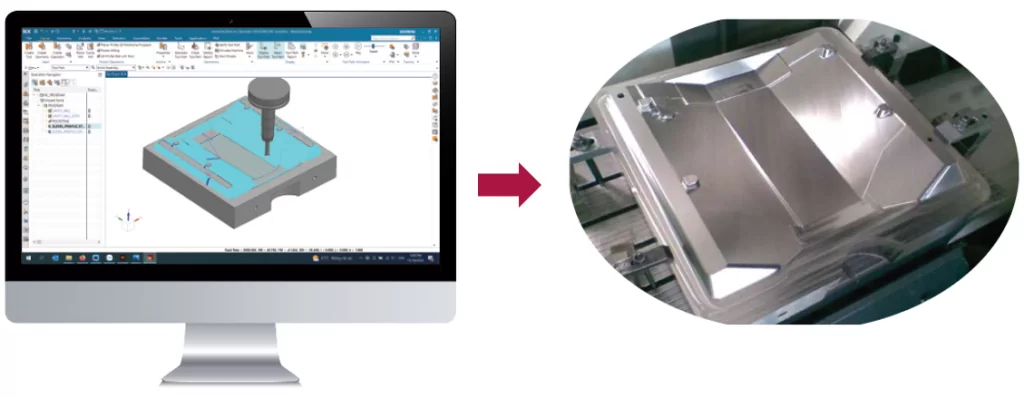

A postprocessor is a software tool that translates the toolpath data generated by CAM (Computer-Aided Manufacturing) software into a format that can be understood by a CNC machine. Essentially, it converts the CAM program’s generic output into specific instructions (G-code) tailored for a particular CNC machine, ensuring that the machine executes the desired operations accurately.

The Role of a Postprocessor

- Translation of Toolpath Data: The primary role of a postprocessor is to convert the generic toolpath data from CAM software into machine-specific G-code. This translation is crucial because different CNC machines and controllers have unique requirements and formats for their instructions.

- Optimization for Specific Machines: Postprocessors are customized to match the specific capabilities and limitations of individual CNC machines. This customization ensures optimal performance and prevents errors during machining.

- Enhancing Precision and Efficiency: By providing accurate and machine-specific instructions, postprocessors enhance the precision and efficiency of the machining process. This leads to higher quality parts and reduced production times.

Why is a Postprocessor Important?

- Ensures Compatibility: A postprocessor ensures that the CAM software’s output is compatible with the CNC machine, preventing potential errors and ensuring smooth operation.

- Reduces Errors: By providing precise instructions tailored to the machine, postprocessors reduce the likelihood of errors that can occur if the machine misinterprets generic toolpath data.

- Improves Efficiency: Optimized G-code generated by postprocessors can significantly improve machining efficiency, reducing cycle times and increasing overall productivity.

Optitech’s Postprocessor Services

At Optitech, we specialize in creating custom postprocessors tailored to the specific needs of our clients. Our services include:

- Customization: We develop postprocessors that are specifically designed to match the unique requirements of your CNC machines.

- Integration: Our postprocessors are seamlessly integrated with your existing CAD/CAM software and CNC machines, ensuring smooth and efficient operation.

- Support and Updates: We provide ongoing support and updates to ensure that your postprocessor continues to deliver optimal performance as your needs evolve.

Optitech also offers an extensive library of postprocessors with thousands of options available for various CNC machines and controllers. To explore our library and find the perfect postprocessor for your needs, visit Optitech Postprocessor Library.

Conclusion

A postprocessor is a critical component in the CNC machining process, ensuring that the CAM software’s output is accurately translated into machine-specific instructions. By enhancing precision, reducing errors, and improving efficiency, postprocessors play a vital role in modern manufacturing. Optitech’s custom postprocessor services are designed to meet the unique needs of your CNC operations, providing the expertise and support necessary for optimal performance.