The precision engineering industry is facing a growing challenge: a shortage of skilled CNC programmers. While experienced machinists are gradually retiring, the younger generation isn’t stepping in fast enough. According to ManpowerGroup’s 2024 Talent Shortage report, 75% of companies worldwide say they can’t find the talent they need – the highest level ever recorded.

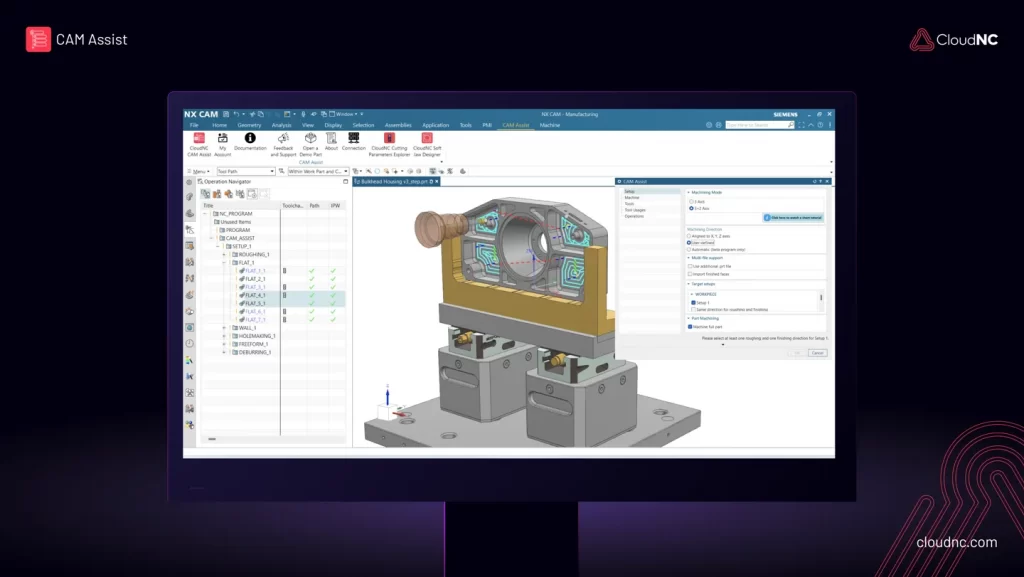

So how can machine shops maintain output and quality without relying entirely on senior programmers? The answer lies in Artificial Intelligence (AI) – particularly in tools like CAM Assist.

AI Doesn’t Replace CNC Programmers – It Helps Them Do More

A great programmer can often become a bottleneck on the shop floor if they are expected to handle all CAM programming themselves. But with AI-powered tools like CAM Assist, they can:

✅ Program parts 5–10 times faster for standard geometries

✅ Focus more on complex jobs that bring higher value

✅ Review and coach junior staff

The result? One programmer can support more machines while maintaining quality and efficiency.

Faster, More Effective Training for New Talent

AI is not only a productivity tool—it’s also a learning accelerator. Junior staff can observe how AI generates toolpaths, learning sequencing, tool selection, and cutting strategies from real-time examples.

This helps companies:

🔹 Shorten onboarding time

🔹 Speed up skill development

🔹 Reduce risk caused by inexperience

Doing More With the Same Team

When hiring is difficult, companies must turn to a strategy of stretching productivity across existing staff. AI-powered CAM tools like CAM Assist are key to making this possible—especially for:

🔹 Small programming teams with a large job queue

🔹 Businesses aiming to scale without increasing headcount

Conclusion: Investing in AI is Investing in Your People

Contrary to fears that AI will replace people, reality is proving otherwise: AI empowers CNC professionals to work faster, smarter, and more efficiently.